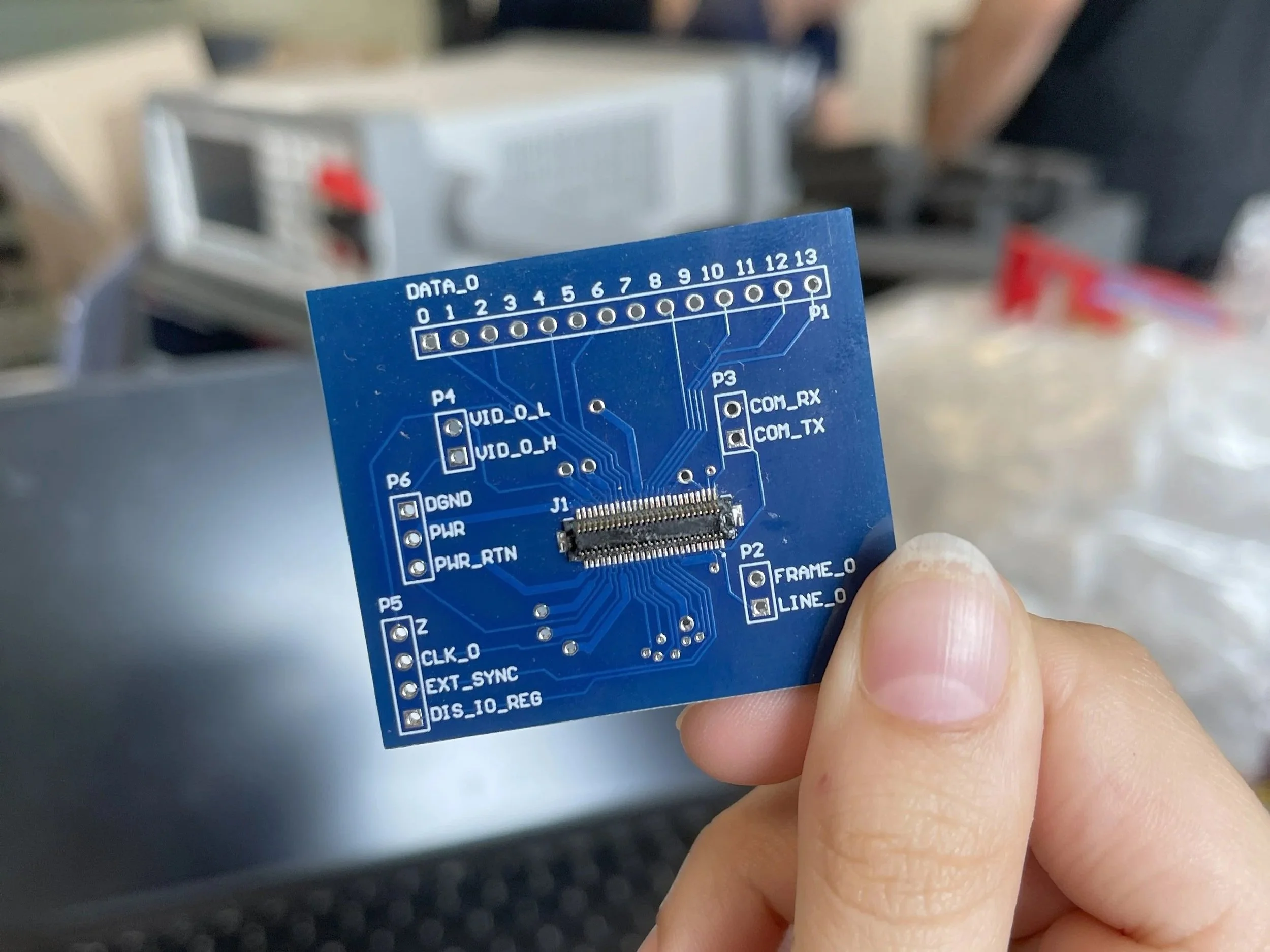

Flex PCB - Custom High Density Camera Connector

The University of Toronto Aerospace Team (UTAT) is currently building a 3U CubeSat to conduct crop residue mapping from Low-Earth Orbit. The payload is a thermal camera, the FLIR TAU, which comes equipped with a 20 mil pitch, 50-pin, board-to-board connector. The board that’s supposed to receive these signals is not physically adjacent to the camera, so a partner and I designed and fabricated a completely flexible PCB to connect the wires in a high-density format that would be able to operate at high speeds (around 70MHz).

A flex PCB ended up being a really cool solution to our problem because its shape is completely customizable and a material called stiffener (PI or FR4) can be used to control the bend area to precisely where we want it in the final satellite. For now, we’ve brought up a short rectangular version as well as a breakout board for testing. When the mechanical subsystem is ready, we’ll revisit this project and redesign for the specific form factor that is needed.

Thanks to this niche experience, I learnt to use the Altium Rigid-Flex Layer Stack Editor, how to layout a board with multiple stack ups, best routing practices in flexible regions, and how to Gerber out all of this information. Soldering a heat-sensitive material that won't lay flat is also a unique challenge.